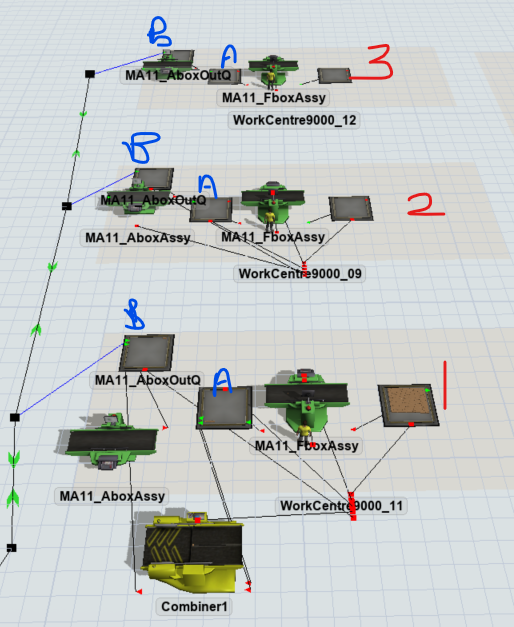

Hi. I recently build a simulation of 3 production lines, which runs according to the production orders. For the current stage of troubleshooing this simulation model we will be discussing/focusing on Line 1 only. will then intend to subsequently extend all the functions to all the 3 lines. all lines have Queue A and B.

I am facing the following issues with my model:

I am facing the following issues with my model:

1) Combiner1 should be receiving flowitems and joining this flowitems into 1. the number of flow items that is to be combined together is dependant on the flowitem label "AboxQty". the combiner will then send the flow item to Queue B.

in the final Queue, Queue B, the flowitems needs to be arrange and stack together in a certain way. for each stack or each layer of flowitems the maximum number must be the same as the global table "FBOX QTY/LAYER" and the maximum for each batch/pallet must be the same as global table "FBOX QTY/PALLET". hence if for example there is a production order of 1000 flowitems that should be in the final queue, and the qty/pallet is 500, qty/layer is 100, we would expect that there would be 5 layers of 100 on the first batch. after pallet is full at 500 all this flowitem would then be move to a sink then the queue will continue to receive the other 500 flowitem.

2) incorporating quality operator activity parallel with production orders activities.

i would like to include the quality operator tasks in the simulation where the operator is required to collect the flowitem at certain times.

- to collect flow item from Queue B AFTER completion of each layer except for the last layer of the pallet.

- to travel to the Queue B AFTER completion of each pallet and perform quality check at the queue for about ~10 seconds before the batch can be transported to a sink

- to collect flow item AFTER every 2 hours from Queue A if the production line is running

if the time period of collecting these flowitems is the same for all the production lines, the operator can then collect all flowitems at the different lines at once assuming that the the trolley that the operator is holding can fit in all flowitems. once all collected the operator will then bring these flowitem back to the quality table and perform inspection (assume 30 seconds for each). if during the time that queue is requesting for a collection for the operator to collect, the operator is busy then these queue willhave to wait till operator is done with all the flowitems that is currently holding and inspection is done. returning the flow items after inspection back to its original queue is to be done after inspection after inspection of all the flowitem that is holding and can be done simulateneuously iwth collecting of the next batch. also if the flowitem has not been return to its original pallet, the pallet cant be release to a sink although all the other items is ready.

test1-1 rev R1.fsm

additional note:

the purpose of this simulation would therefore be to study the efficiency of quality operators throughout the different production orders scenario.

the efficiency can be studied from the total time taken for inspection, total idling time, total walking time and lastly the time it takes for flow item to be collected, inspected and return.