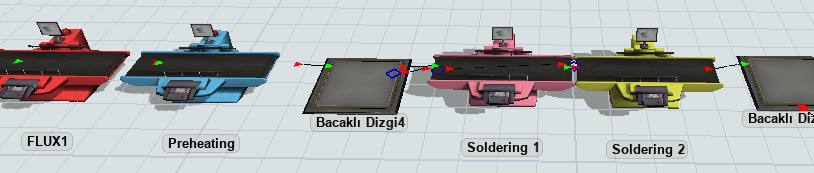

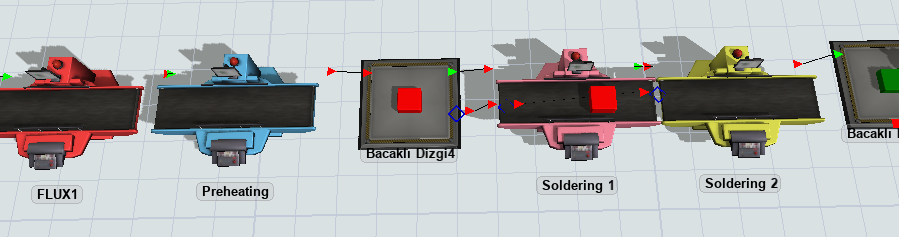

In real life production, the card enters 1 machine (called seho) and goes through 3 processes. The operations in seho are flux preheating and soldering, respectively. However, there is a feature in the machine: there are 2 heads in the soldering stage, meaning that soldering can be done to 2 cards at the same time. But there is a condition for this. After the card goes through the flux preheating soldering stages, it goes to the 1st head of the solder and solders are made. If the card coming from behind has not finished the preheating step (flux may be empty, preheating may be empty or preheating may be in progress etc.), the previous card continues the soldering process in the soldering1 head. However, if the card coming from behind has left the preheating, meaning it is waiting in line for soldering, the card in front goes to soldering2 and continues the soldering process from where it left off. The card coming from behind also goes to soldering1 and starts the soldering process. In other words, soldering can be done in both heads at the same time. But there are cases where this does not happen. In other words, while the soldering process of the card in front is about to finish in soldering1, the card coming from behind may still be in the flux step. Therefore, the card in front may come out without any soldering process in soldering2.

What I want from you is to create this environment in flexsim. I added a queue after preheating. In this way, when there is a card in the queue (maximum can be 1 card), the card in solder1 should immediately switch to solder2. But I could not fulfill this condition.

.

.