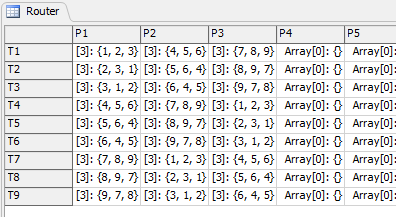

Hallo, I’m working on a Job Shop model where each product has its own specified batch size. In my model, products wait in the control flow until they reach their specified batch size. Once the batch size is met, the products move to the station_queue to wait for processing. For example, Product ELM100 can be processed at Stations 1, 2, and 3. However, the queue for Station 1 (station1_queue1) has a maximum capacity of 100 products. If station1_queue1 reaches its limit, I want Product ELM100 to automatically move to the queue for Station 4 (station4_queue1), as it can also be processed there.

Is this behavior possible to configure in FlexSim? If so, could you provide guidance or best practices on how to set this up?

Thank you for your insights and assistance! Jobshop Experimenter 23 SC1 Testing.fsm